VERONA, WI –Cleary Building Corp. is proud to announce it is starting its 49th year…

Types of Doors for Farm Machine Sheds and Shops

How to Choose the Right Door for Equipment Access, Efficiency, and Long-Term Use

Modern farm buildings are designed to handle today’s larger, more complex equipment. Because of that, door selection plays a critical role in how well the building functions—especially when the space is heated, used year-round, or expected to adapt as equipment changes. Each door type offers distinct advantages depending on building layout, equipment size, traffic patterns, and weather exposure. Understanding how these doors perform helps ensure your building works the way you need it to for years to come.

Determining Door Size and Placement

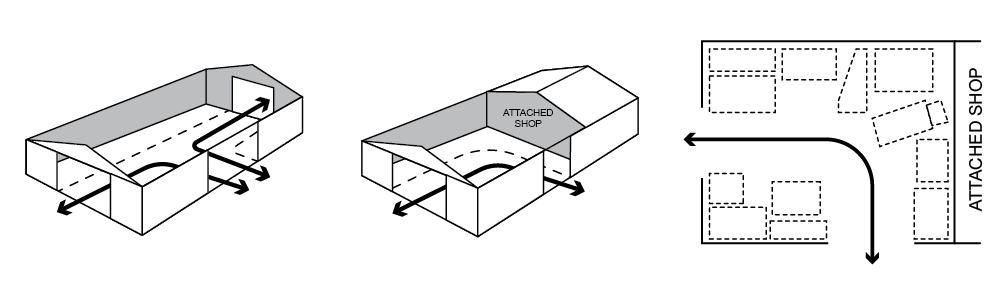

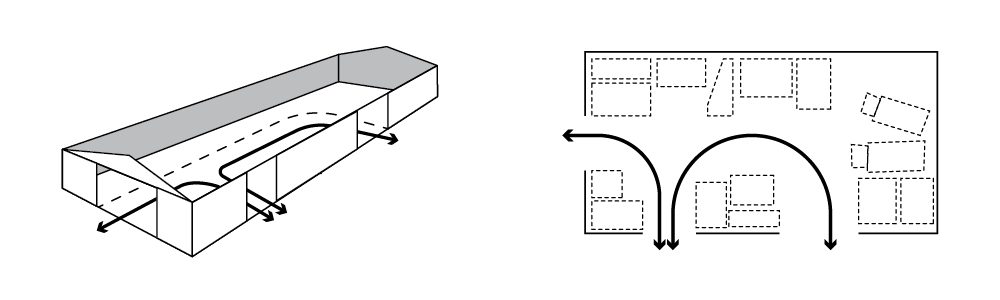

Before finalizing door sizes and locations, it’s important to step back and determine what overall building type and layout will best fit the operation. The way a machine shed or shop is configured has a direct impact on traffic flow, storage efficiency, and how easily equipment can be moved in and out. Considering equipment movement early in the planning process helps establish the most effective building configuration and door locations.

Doors between 13 and 15 feet tall will accommodate most farm equipment, though specialty crops and large-scale operations may require additional clearance. Large tractors and self-propelled combines typically measure between 10 and 12½ feet to the top of the cab, with exhaust stacks extending another 6–8 inches. Equipment like twelve-row combines often require door widths of up to 40 feet and heights between 16 and 18 feet. Large fold-up equipment may require as much as 21 feet of headroom. When planning for clearance, don’t forget to account for lighting fixtures, radiant heat tubes, overhead cranes, and future interior additions.

L-Type Traffic Flow Pattern |

U-Type Traffic Flow Pattern Between Side Doors |

|

|

Sliding Doors

Sliding doors are a common and economical choice for machine sheds and unheated storage buildings. Cleary standard slide doors can be insulated and weather stripped, but even with these features, sliding doors will not provide a fully weather-tight seal. For heated spaces where energy efficiency is a priority, this is an important consideration. Standard sizes include solid doors up to 20 feet wide and split doors up to 30 feet wide with a 17-foot truss clearance.

For larger openings, Plyco slide doors are designed for lighter, smoother operation and wider spans, reaching up to 36 feet wide in split configurations with a 19-foot truss clearance. When placing sliding doors in a sidewall, sizing them to match truss spacing results in the cleanest installation. For example, buildings with trusses spaced 9 feet on center pair well with 18- or 27-foot doors, while 10-foot spacing works best with 20- or 30-foot doors.

Bi-Fold Doors

Bi-fold doors are wide, upward-folding doors commonly used in airplane hangars and machine storage buildings that house large equipment. For farm machine sheds storing oversized machinery, bi-fold doors are often a more effective solution than extra-large sliding doors.

Bi-fold doors are wide, upward-folding doors commonly used in airplane hangars and machine storage buildings that house large equipment. For farm machine sheds storing oversized machinery, bi-fold doors are often a more effective solution than extra-large sliding doors.

One of the key design considerations with bi-fold doors is hinge height. Each manufacturer has specific requirements that influence the eave height needed to achieve a desired clear opening. Some door designs require a taller building than others for the same door clearance. Based on past experience, Hi-Fold doors often allow for lower hinge height locations, depending on door size, which can reduce overall building height while still providing adequate clearance.

Hydraulic Doors

Hydraulic doors serve a similar purpose to bi-fold doors but operate as a single, one-piece door that swings upward. In many cases, hydraulic doors require less headroom than bi-fold designs, which can help limit building height. Because hydraulic doors swing outward as they open, additional clearance is required in front of the building, and snow removal may be necessary before opening during winter months.

Hydraulic doors typically have fewer moving parts than bi-fold doors, though power supply and maintenance requirements differ between the two systems and should be reviewed during planning.

Overhead Doors

Overhead doors are commonly used for service vehicles, smaller equipment, and daily access points. When equipped with openers, they offer convenient operation and reliable performance. For heated portions of a farm shop, insulated overhead doors provide the most energy-efficient solution. Track placement should be carefully planned to avoid interfering with taller machinery, and high-lift track systems may help maintain needed clearance.

Clopay offers large sectional overhead doors with removable center mullions. This allows two doors to function as one wide opening when needed, while still allowing one door to remain closed for routine access.

Walk Doors

Walk doors provide convenient access to the building and equipment and are especially important in larger machine sheds and shops. Most larger buildings benefit from having at least two walk doors to allow easy exterior access in case of an emergency. Features such as kick plates, latch guards, and deadbolts can improve durability and security, while a concrete landing with a boot scraper helps stabilize high-traffic areas and keep the shop cleaner

Large Door Type Comparison

Door Type |

Best Use |

Weather Performance |

Clearance & Space Needs |

Key Considerations |

|---|---|---|---|---|

| Sliding Doors | Unheated machine sheds | Not weather tight | Requires clear wall space | Economical, simple design |

| Bi-Fold Doors | Large equipment storage | More weather tight than sliding | Opens upward, minimal front clearance | Hinge height affects eave height |

| Hydraulic Doors | Large, wide openings | Often more weather tight | Swings outward, needs front clearance | Fewer moving parts |

| Overhead Doors | Heated shops, daily access | Most energy efficient | Track placement required | Best option for heated spaces |

Plan Your Door Layout with the Whole Building in Mind

Choosing the right door system for your farm machine shed or shop isn’t just about today’s equipment. Door size, placement, and style affect traffic flow, energy efficiency, and how easily your building can adapt as operations change. A Cleary Building specialist can help evaluate your equipment, layout, and long-term goals to ensure your building is designed to work for you well into the future.

Talk with a Cleary Building Specialist

Start planning your machine shed or farm shop with confidence. Contact your local Cleary Building specialist to discuss door options and building design.